Polystyrene Recycling Gains

Posted on 09/04/2025

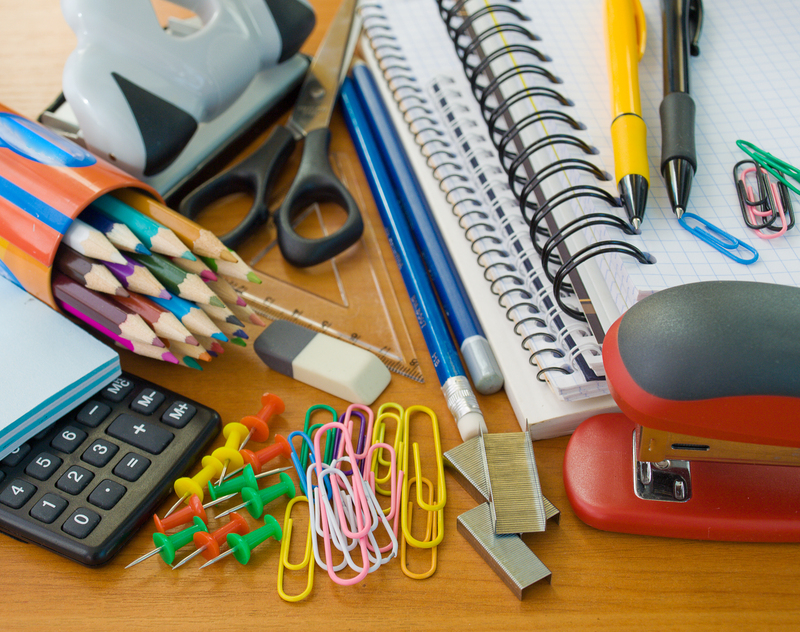

Polystyrene, commonly known by the brand name Styrofoam, is a widely used plastic found in various products ranging from packaging materials to insulation. While its practicality is undeniable, the environmental impact of polystyrene is a growing concern. Accumulating in landfills and oceans, it poses significant challenges to waste management systems globally. However, recent advances in polystyrene recycling techniques are offering promising solutions.

Understanding Polystyrene: Properties and Challenges

Polystyrene is a synthetic aromatic hydrocarbon polymer made from the monomer styrene. Its lightweight and versatile nature makes it an ideal material for various applications, including food packaging, disposable cups, and building insulation. Despite its utility, polystyrene is notorious for its environmental footprint due to its non-biodegradable nature.

The primary challenges of polystyrene include:

- Voluminous waste: Polystyrene products take up considerable space in landfills because they are not compact easily.

- Poor biodegradability: Natural decomposition of polystyrene can take hundreds of years.

- Environmental pollution: Improper disposal often leads to polystyrene litter in oceans and natural landscapes.

- Chemical leaching: Chemicals from polystyrene can leach into food or beverages, raising health concerns.

Advancements in Polystyrene Recycling Technologies

Traditional methods of recycling polystyrene, such as mechanical recycling, have shown limited success due to the low density and contamination issues of the material. However, new methodologies are emerging, providing more efficient and sustainable solutions. Some of these methods include:

Thermal Densification

Thermal densification involves heating polystyrene to a high temperature, reducing its volume significantly. This technique transforms bulky polystyrene waste into dense, manageable blocks that can be easily transported and processed. Thermal densification also enables the creation of oil-like products that can be repurposed in other industrial applications.

Solvent-Based Recycling

In solvent-based recycling, polystyrene is dissolved in a solvent, breaking it down into a workable liquid form. The solution can then be purified and re-solidified into new polystyrene products with near-virgin quality. This method minimizes contamination and retain the material's original properties.

Biological Recycling

An exciting development in polystyrene recycling is the use of microbes to break down polystyrene. Certain bacterial strains, such as Ideonella sakaiensis, have shown potential in degrading polystyrene. This method is still in the experimental stages but offers a natural and sustainable approach to managing polystyrene waste.

The Role of Legislation and Corporate Responsibility

Effective recycling programs cannot succeed without strong legislative frameworks and corporate responsibility. Governments worldwide are beginning to recognize the importance of regulating plastic waste and encouraging recycling initiatives through laws and incentives. For instance, the European Union's Single-Use Plastics Directive aims to reduce plastic waste substantially, promoting recycling and the use of sustainable alternatives.

Corporations also play a crucial role in promoting polystyrene recycling. Major companies are investing in advanced recycling technologies and rethinking product designs to minimize waste. Initiatives such as the Circular Economy Package by multinational corporations aim to create closed-loop systems where products are continuously recycled and reused.

Local and Global Initiatives in Polystyrene Recycling

Several local and global initiatives are making significant strides in polystyrene recycling. For example:

Global Recycling Network

The Global Recycling Network connects recyclers, governments, and corporations around the world to share best practices and technologies. By fostering a collaborative approach, this network aims to streamline the recycling process and reduce waste.

Extended Producer Responsibility Programs

In countries like Germany and Japan, Extended Producer Responsibility (EPR) programs hold manufacturers accountable for the entire lifecycle of their products, including waste management. These programs incentivize companies to design more recyclable products and invest in recycling infrastructure.

Community-Based Recycling Initiatives

Grassroots initiatives at the community level are also playing a significant role. For instance, local collection programs and educational campaigns in cities across the United States encourage residents to participate in recycling efforts actively.

The Future of Polystyrene Recycling

The future of polystyrene recycling looks promising, thanks to ongoing technological advancements and increased awareness of environmental issues. Innovations such as enzymatic recycling and the development of biodegradable polystyrene alternatives are on the horizon. Additionally, increased investment in recycling infrastructure and global cooperation will further enhance the effectiveness of recycling programs.

However, to realize the full potential of these advancements, a multi-faceted approach is needed. This includes:

- Consumer Education: Educating the public on proper recycling practices and the importance of waste reduction.

- Incentivizing Recycling: Providing incentives for individuals and businesses to participate in recycling programs.

- R&D Investment: Investing in research and development to discover more efficient and sustainable recycling methods.

- Global Collaboration: Enhancing international cooperation to share knowledge and resources.

Conclusion

Polystyrene recycling gains significant importance in today's context of environmental sustainability. By embracing innovative recycling technologies and fostering a culture of responsibility among consumers and corporations, we can mitigate the adverse effects of polystyrene waste. As technological advancements continue to emerge, and with adequate legislative support and global cooperation, the dream of a sustainable, circular economy without polystyrene waste may soon become a reality.

In the end, the collective effort of individuals, businesses, and governments will be crucial in ensuring a greener planet for future generations.